MACHINE WIRING

Order, cleanliness and strength, because machine must not only works.

Our working process.

Increasing importance is given to the connection of the machine to the electrical panel: the machine wiring dresses the mechanics, and must be tidy and strength. Our Machine Wiring meet the needs of:

- Attention to the place of work, to choose suitable cables, oilproof, for flexible laying, for high temperatures, for environments subject to electromagnetic noise

- Flexibility, for supplies in wiring kits, where the customer can by itself connecting the machine to the electrical panel

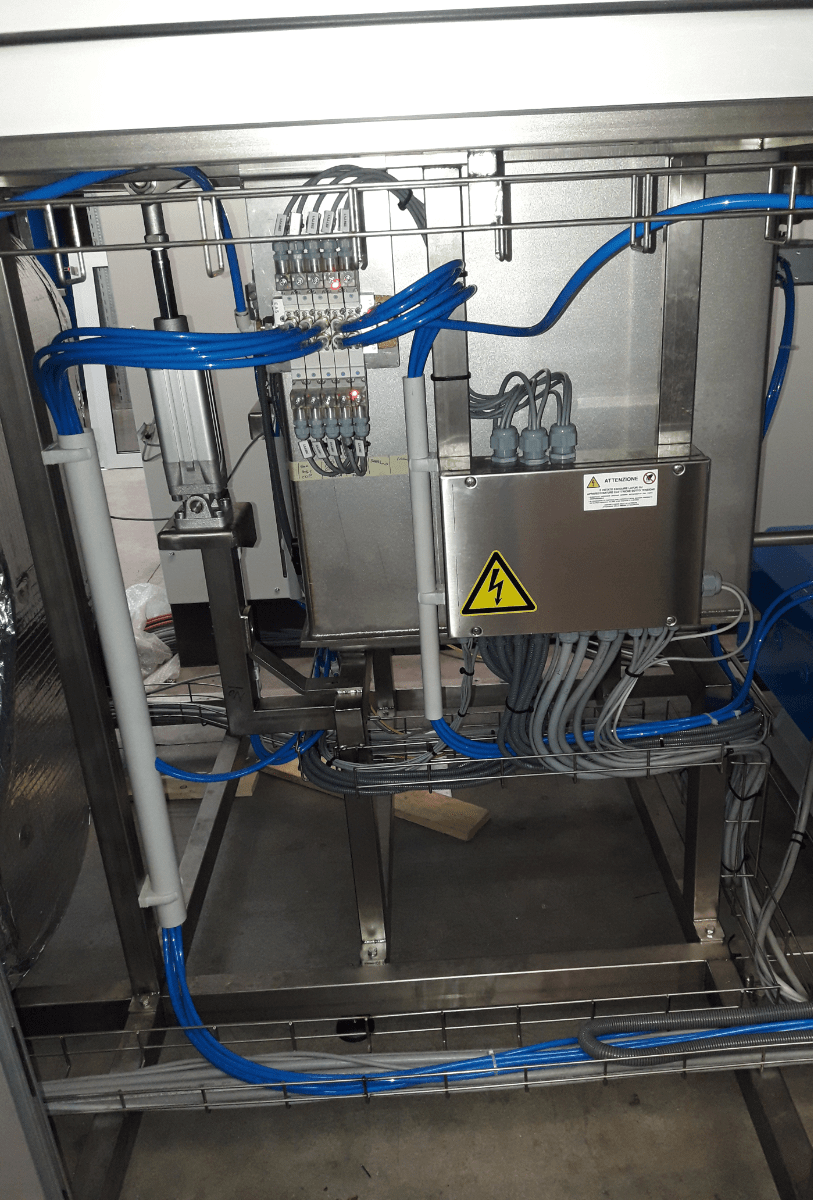

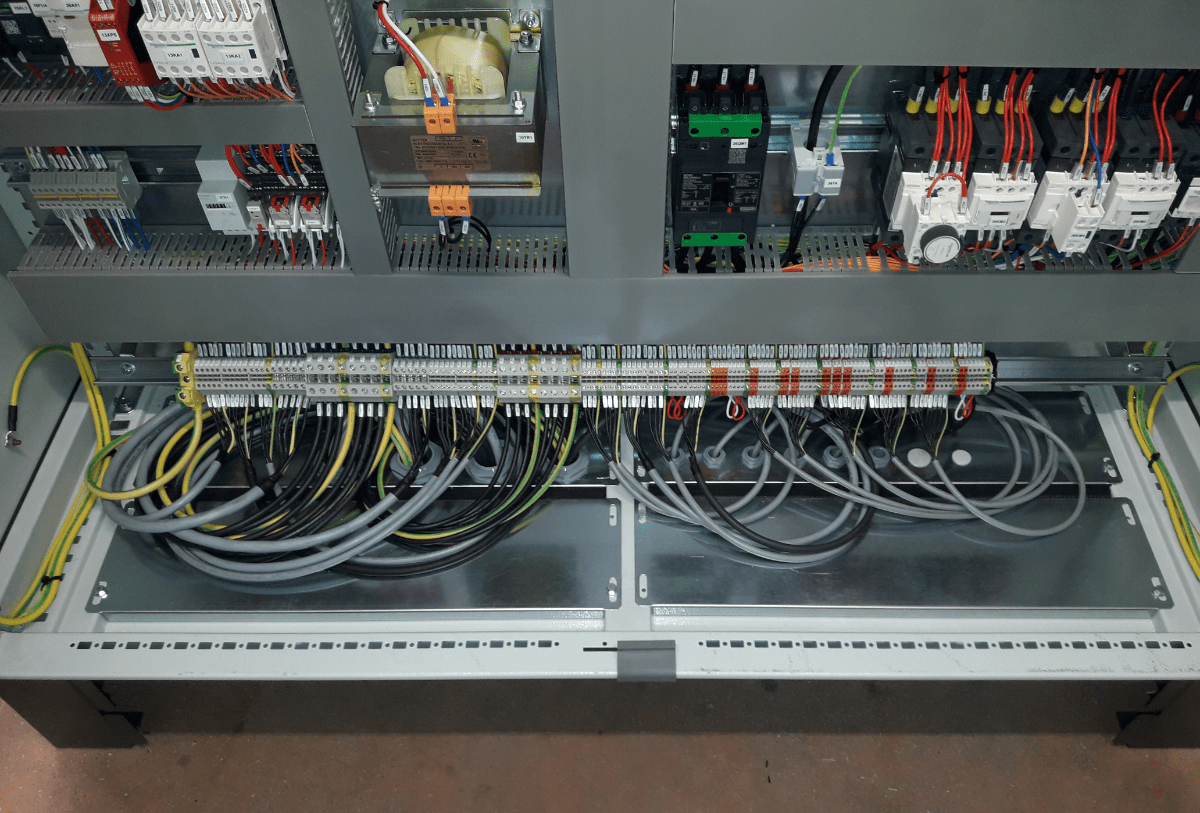

- Strength, with cables protected by plastic sheaths or with metal core, TAZ metal conduits, metal cables trays, iron or stainless steel boxes.

It is our usually to study the Machine Wiring according to the needs of the machine and its manufacturer.

So we propose:

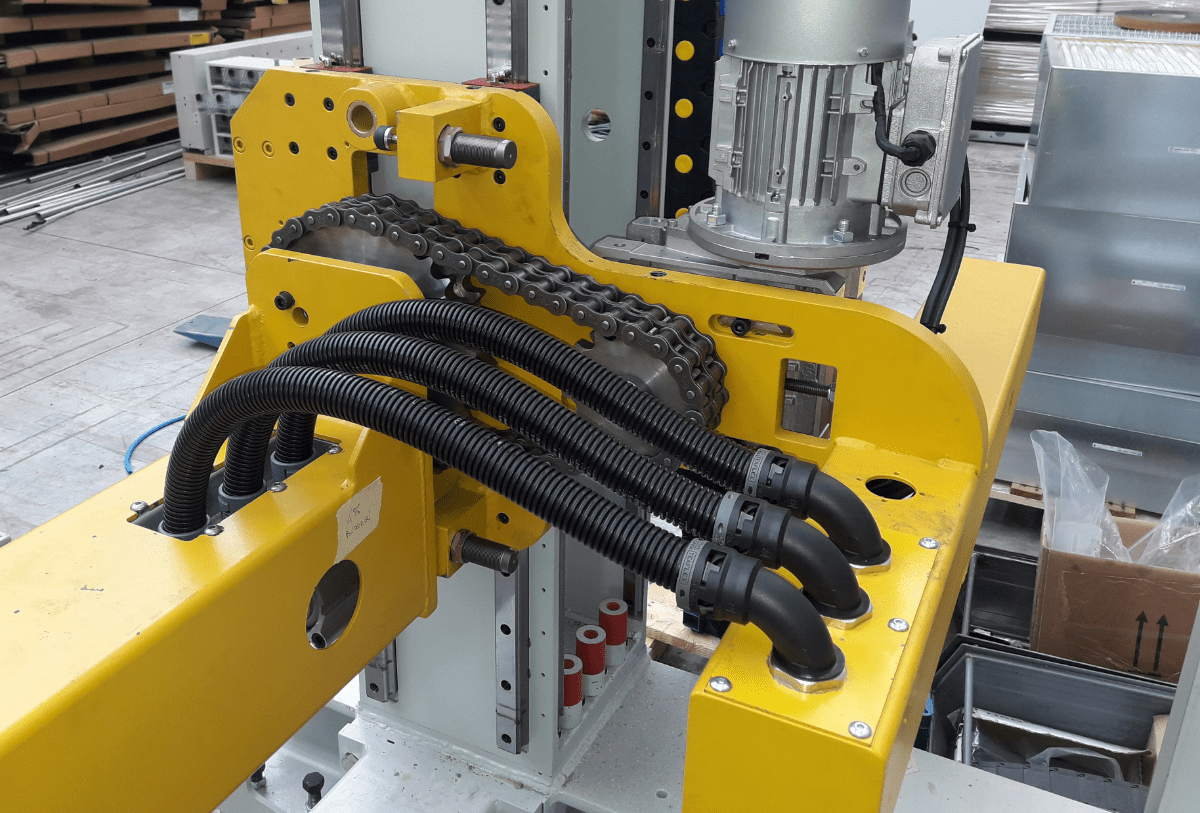

- Polyamide Flexible Conduits

- Conduits with iron core

- Open, perforated or closed metal cable trays, with customized curves and joints

- Standard and shielded oil-proof cables for fixed installation

- Cables for flexible laying for speeds up to 600m/min

- Cables made in silicon or coated for high temperatures

- ATEX classified solutions for potentially explosive areas

Highlights:

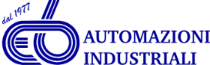

- ATEX junction box, encoder, motor

- Cable ascent, metal flexible conduits

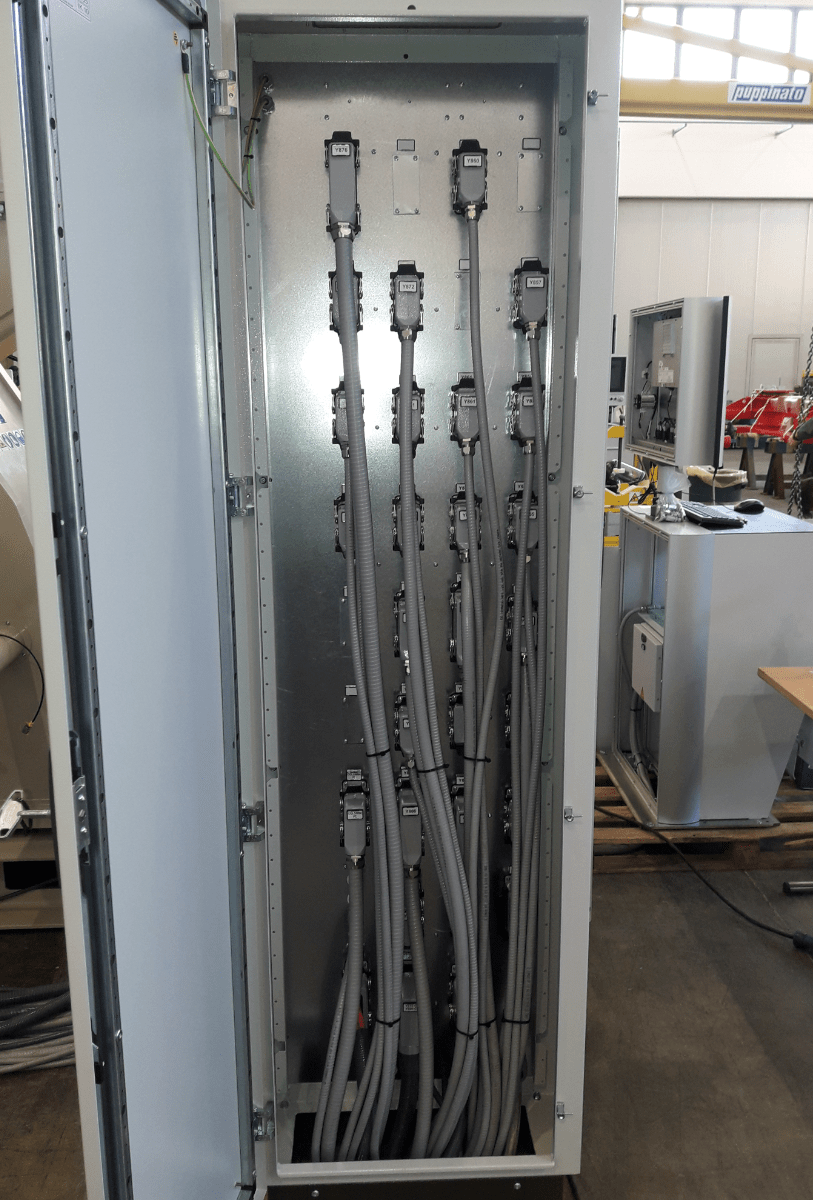

- Energy chains, cables for flexible laying motion

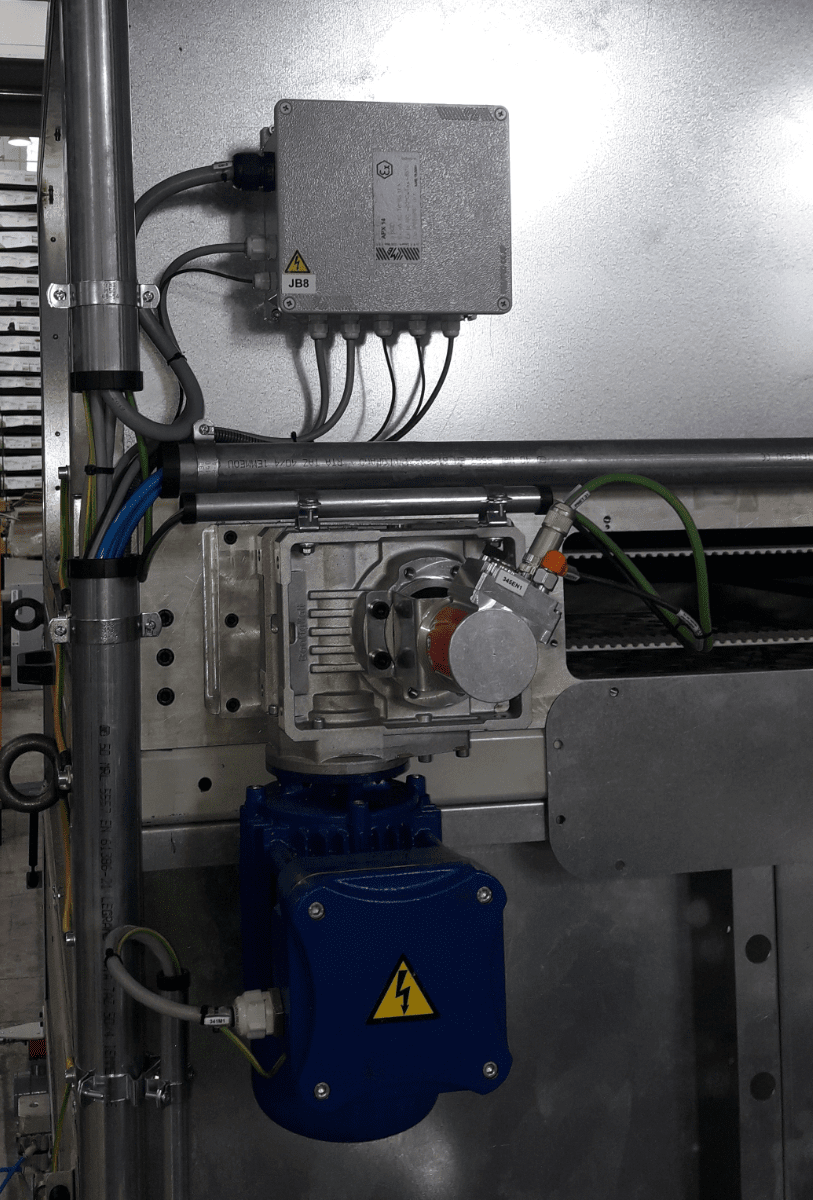

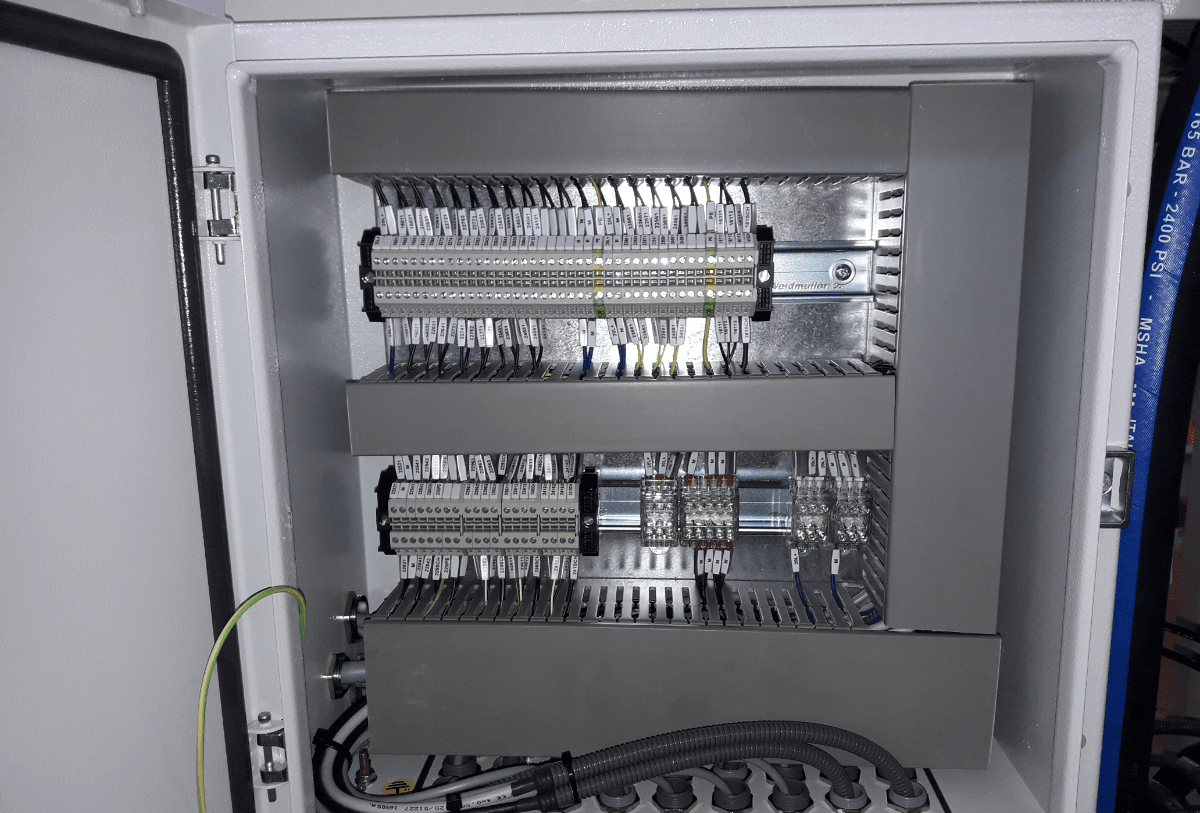

- Junction box, internal view

- Flexible sheath for robotics

- Laying of closed metal channel

- Laying of open metal ducts, junction boxes in stainless steel

- Cabinet cable entry, on the machine supplied already wired

WE CONTACT YOU

Leave us little information and you will be contacted as soon as possible.